Enclosures and Connectors: A Comprehensive Guide for Engineers

Enclosures are protective cases that house and safeguard electronic and electrical components from environmental factors. Connectors, broadly speaking, are devices that join electrical circuits together, and also protect them.

"Enclosures & Connectors" is one of the five pillars of expertise and product offerings supported by ArKco Sales (the others are Power, Thermal, HMI, and Electrification). Grouping these together makes sense for an electromechanical manufacturers sales rep, because they serve complementary roles in system integration.

For the engineers, OEMs, and distributors who our customers, this approach simplifies product selection, procurement, and part replacement processes. It allows you to better see synergistic lines for design compatibility, and streamlines sales and support.

In this article we’ll describe the various categories of enclosures and connectors used by engineers in product and facility design, along with specific types. For each we name the specific manufacturers whom we’ve vetted and whose products we offer. We also provide a list of products by industry for easy discovery.

Table of Contents

Enclosures

.....What to Look For: sourcing considerations for enclosures

.....General purpose enclosures

.....EMI/RFI shielded enclosures and board-level shielding

.....Modular enclosures

.....Industrial enclosures

.....Climate-controlled enclosures

.....Harsh-environment and portable enclosures

.....DIN rail mount enclosures

Connectors

.....Circular connectors

.....Board-level connectors

.....Electrical connectors: Busbars and fuse blocks

.....EMI seals and gaskets

.....Wireless connectors and sensors

.....Cable management

Products by industry

Products by category

Enclosures

Electrical enclosures are designed to house electrical and electronic components, protecting them from environmental factors and unauthorized access, and providing connectivity, monitoring ability, and control.

Typically made from durable materials like steel, aluminum, or plastic, enclosures are used across various industries due to their adaptability and reliability.

Common industrial applications include housing control panels in manufacturing plants, protecting junction boxes in construction sites, and encasing electronic equipment in telecommunication facilities.

Their robust design ensures components remain secure and functional, making them essential for maintaining the integrity and performance of critical systems in diverse environments.

What to Look For: Sourcing Considerations for Enclosures

You may already know this, but when selecting an enclosure, there are several factors and criteria to consider. Where relevant, it’s a good idea to know your requirements for each of these before requesting a pricing quote from a manufacturer or sales rep.

Material and durability. Designers often must ensure the enclosure can withstand environmental conditions like dust, moisture, vibration, or extreme temperatures, especially in industrial or outdoor settings. Metal enclosures, such as those made from steel or aluminum, provide robust strength, while plastic options like polycarbonate or ABS offer lightweight and corrosion-resistant properties.

Environment and protection ratings. These include IP (ingress protection) ratings for dust and water resistance or NEMA ratings for U.S. applications, to help in evaluating enclosure resistance to elements; engineers look for ratings that meet specific environmental needs (e.g., IP65 for water resistance or NEMA 4X for corrosion resistance).

For applications involving extreme temperatures or sensitive electronics, climate-controlled enclosures or those with EMI/RFI shielding are advisable. Enclosures may need conductive coatings, gasketing, or specific materials to shield against EMI/RFI without affecting performance.

Size and compatibility. The enclosure should fit the components and available space precisely, with appropriate mounting options for wall, rack, or floor installations. This is especially true in densely packed electronics or designs with heat-producing elements. Dimensions must accommodate equipment without cramping, and designs must ensure ease of access for assembly, maintenance, or cooling.

Compliance and certifications. Compliance with industry standards and certifications, such as UL, IEC, or CSA (or ATEX or IECEx for hazardous locations), is essential for safety and regulatory adherence. Certifications for fire resistance, EMI/RFI shielding, and mechanical strength are critical, especially in applications like medical, military, or hazardous environments.

Accessibility and maintenance. Enclosures with removable panels or hinged doors provide easy access, and ease of installation and maintenance should be evaluated.

Cost. Ensure that the enclosure fits within budget while meeting all necessary features. Also, overall lifetime cost of ownership may be an important consideration, as long-term cost savings may outweigh initial pricing.

Design and aesthetics. Enclosures that are installed in visible or public areas contribute to the overall professional appearance, branding, and integration with the surrounding environment. A well-designed enclosure can also enhance user experience by incorporating intuitive features and ergonomic elements that make it easier to access and interact with the housed components.

Manufacturers and Products:

- nVent Schroff: Cabinets and Racks, Indoor

- nVent Schroff: 19” cases

- Noark Electric: Enclosed Electrical Breakers

- Italtronic: DIN rail mounted Enclosures

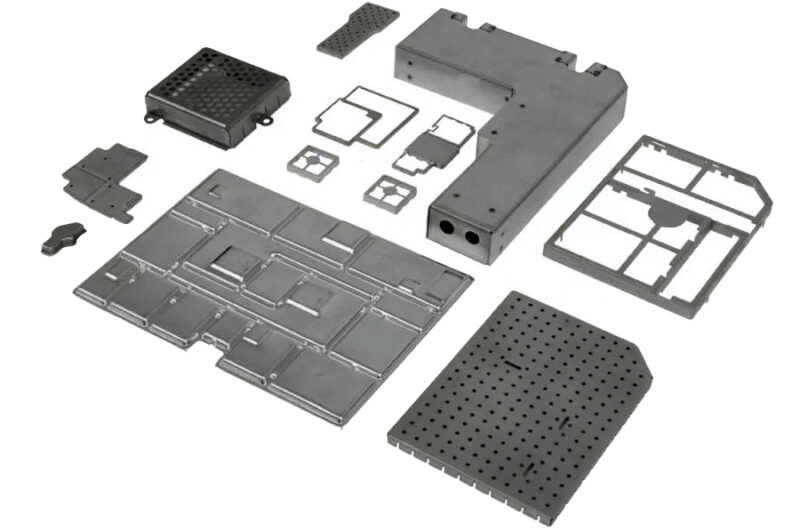

EMI/RFI Shielded Enclosures and Board-Level Shielding

These specialized housings are designed to block electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring the reliable operation of sensitive electronic equipment.

They feature conductive coatings or materials, such as metal or conductive-coated plastic, which effectively attenuate EMI/RFI signals. They often include gasketed seals, grounding points, and filtered ventilation to maintain shielding effectiveness while allowing necessary airflow and access.

EMI/RFI shielded enclosures feature high shielding effectiveness, robust construction, and compliance with industry standards for electromagnetic compatibility (EMC). They’re commonly used in industries where maintaining signal integrity is critical, such as telecommunications, medical devices, aerospace, and defense.

- In telecommunications, they protect network equipment from interference that could disrupt data transmission.

- In the medical device field, they ensure the accuracy and reliability of diagnostic and imaging devices.

- Military and aerospace applications use these enclosures to safeguard avionics and communication systems from external electromagnetic threats, ensuring mission-critical performance.

The size of EMI/RFI shielded enclosures can vary widely. Typically, they range from small board-level shielding (BLS) enclosures measuring just a few inches on each side, used for protecting individual circuit boards or small electronic devices, to large cabinets and rack-mount units that can be several feet in height and width, designed to house entire systems or multiple pieces of equipment.

Manufacturers and Products:

- Laird Dupont: Board-Level Shielding

- nVent Schroff: EMI Shielded 19” Cabinet Enclosures

- nVent Schroff: EMI Shielded Small Form-Factor Rugged Cases

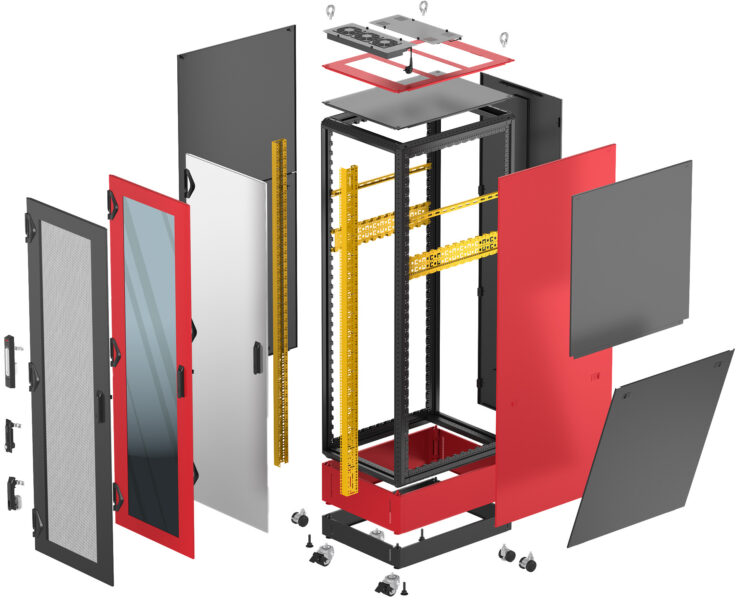

Modular Enclosures

Modular enclosures are by definition flexible and customizable, designed to accommodate varying sizes and configurations of electronic and electrical components. They include electronics cabinets, cases, and integrated systems like PXIe chassis. These enclosures feature modular panels, adjustable frames, and a wide range of accessories, allowing for easy expansion, reconfiguration, and integration of different components.

Key elements include robust construction, advanced cooling options, and high flexibility in design, enabling tailored solutions for specific applications. The enclosures often come with options for enhanced EMI/RFI shielding, ventilation, and secure access points.

Common industrial applications of modular enclosures include data centers, where they house servers and networking equipment; industrial automation, where they protect control systems and machinery interfaces; and telecommunications, where they accommodate diverse networking gear.

Their adaptability makes them ideal for environments requiring frequent updates or expansions, ensuring long-term viability and efficiency in rapidly evolving technological landscapes.

Manufacturers and Products:

- nVent Schroff: Varistar CP

- nVent Schroff: RatioPac PRO Style

- Italtronic: DIN rail mounted enclosures

Industrial Enclosures & Breakers

Many industrial settings—including agriculture, construction, and military—require robust protective enclosures to withstand harsh environmental conditions.

Core features include high durability, corrosion resistance, impact resistance, and often weatherproof or waterproof seals to protect internal components from dust, moisture, and mechanical damage. They may also feature design elements for advanced shock and vibration protection.

Typically made from materials like stainless steel, heavy-duty plastic, or aluminum, these enclosures provide strong protection and longevity. They also often incorporate advanced cooling and ventilation systems to maintain optimal operating temperatures for housed equipment.

Products like nVent Schroff’s Varistar CP electronics cabinets and Noark Electric’s industrial molded case circuit breakers, are quite excellent at securing sensitive electronics and electrical components, and ensuring operational integrity and safety in demanding sectors.

Manufacturers and Products:

- nVent Schroff: Rack Safety PLUS - PDU with Emergency Stop

- nVent Schroff: Varistar CP - Modular Electronics Cabinets

- Noark Electric: Power Breakers

- Italtronic: DIN rail mounted enclosures

Climate-Controlled Enclosures

Climate-controlled enclosures are designed to maintain optimal internal temperatures and humidity levels for sensitive electronic and electrical components. Constructed from durable materials like insulated metal or heavy-duty plastic, these enclosures feature built-in cooling systems, heaters, and sometimes humidity control elements to protect against extreme temperatures and moisture.

These enclosures are typically found in industries that rely heavily on rooms—or even warehouses—full of surplus heat-generating electronics.

In telecommunications, they safeguard outdoor networking equipment. In industrial automation, they protect control systems in variable climates. In and medical device and test and measurement laboratories, they ensure stable conditions for sensitive instruments.

nVent Schroff offers a range of temperature-controlled enclosures designed to protect sensitive electronic and electrical components from extreme temperatures.

- The Varistar Series provides robust protection with advanced thermal management solutions, including options for active and passive cooling, making it ideal for data centers, telecommunications, and industrial automation where precise temperature control is critical.

- The Interscale M Series features compact enclosures with integrated cooling solutions suitable for small to medium-sized electronics, offering passive and active cooling, EMI shielding, and tool-free assembly, perfect for IT infrastructure, medical devices, and industrial applications.

Other enclosure cooling options from Schroff include:

- VITA Compliant Conduction Cooled Assemblies

- Liquid cooling via Coolant Distribution Units (CDUs)

- Rear door heat exchangers for 19-inch cabinets

- In-row air-water cooling units

- 19" fan trays

Manufacturers and Products:

- nVent Schroff: [Data Center Cooling] (https://schroff.nvent.com/en-u...)

- nVent Schroff: [Enclosure Heating and Ventilation] (https://schroff.nvent.com/en-u...)

For more information about cooling and thermal management, or if you're looking for information about thermal interface materials (TIMs), please see our Thermal Management Guide feature!

Harsh-Environment and Portable Enclosures

Field use demands lightweight, durable enclosures designed for easy transport. Constructed from materials like polycarbonate, ABS plastic, or lightweight metal, these enclosures often feature handles, shoulder straps, and ruggedized designs to protect against drops and impacts.

They are widely used in industries such as field diagnostics, portable testing, and military applications, where equipment needs to be transported and operated in various environments. nVent Schroff offers products like the IP-Pro Alu EMC series or small form-factor rugged cases, and the, which provide robust protection and ease of use with features such as shock absorbers and weather-resistant seals.

The die-cast aluminum enclosure IP-Pro Alu EMC from nVent SCHROFF offers robust IP protection up to IP67, is EMC shielded, as well as shock, vibration and weather resistant. It can be configured for electronics with standardized or customer-specific form factors.

Schroff also offers ruggedized cabinets to meet the needs of defense applications with high shock and vibration requirements, as well as a certified product platforms for MIL-STD-901D and earthquake resistance up to Belcore Zone 4.

Manufacturers and Products:

- nVent Schroff: Varistar CP MIL 901E Cabinet, Military Certified for Shock, Vibration, EMC, and Corrosion

- nVent Schroff: IP-Pro Alum EMC - Small Form Factor Rugged Cases

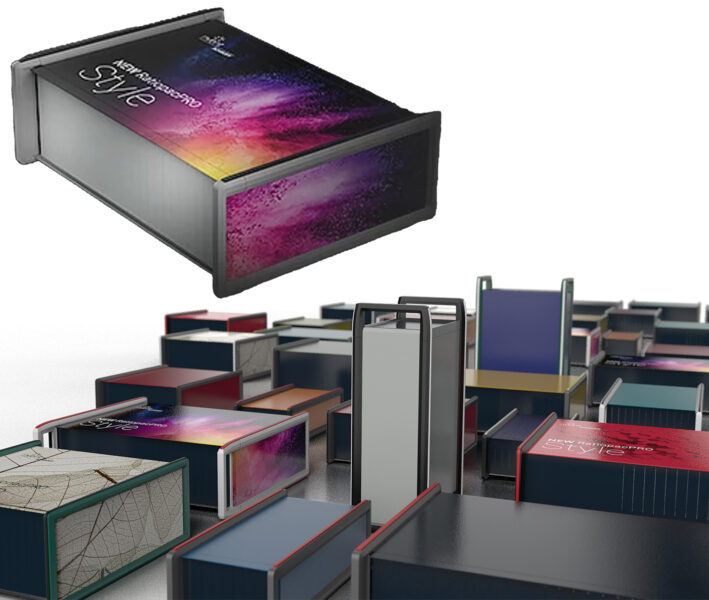

Desktop Cases and Standardized Modular Systems Chassis

Desktop electronics cases come in an enormous range of sizes, styles, and configurations, from 19" subracks to custom cases for desktop computing, test and measurement, and specialized industrial electronics applications.

It's easy enough to find an inexpensive grey or beige steel case that can house a CPU and some fans. But for unique commercial and industrial applications, or for mass-produced white label solutions, quality options can be harder to source.

For it's flexibility and design options, nVent Schroff's RatioPac PRO Style is one of the most versatile and branding-friendly configurable desktop cases on the market. It's available in a range of colors, sizes, instrumentation, ventilation, handles, and full-color design options. And Schroff's configurators are famously well-designed and easy to use: see the RatioPac PRO Style configurator here.

Standardized modular systems architectures like AdvancedTCA, MicroTCA, CompactPCI, PXIe, VME/VME64x, and VPX are typically used in embedded computing applications, particularly in military and industrial manufacturing. Each offers different form factors and performance levels, with the key difference being their size, data transfer speeds, and specific features designed for different needs. Essentially, they are different standards for building complex computer systems on a backplane.

- AdvancedTCA (Advanced Telecom Computing Architecture): A high-performance, modular standard with large form factor boards, often used in demanding applications like telecommunications and network infrastructure.

- MicroTCA (Micro Telecom Computing Architecture): A smaller version of AdvancedTCA, offering similar functionality but in a more compact size, ideal for space-constrained applications.

- CompactPCI: A widely adopted standard with a smaller form factor than AdvancedTCA, providing a balance between performance and size, suitable for industrial and military applications.

- VME (Versa Module Eurocard Bus): An older, established standard known for its ruggedness and reliability, often used in military and harsh environment applications.

- VME64x: An extension of the VME standard with increased data transfer capabilities.

- VPX (VITA 46): Considered the modern successor to VME, offering significantly higher bandwidth and advanced features for demanding military and aerospace applications.

nVent SCHROFF offers solutions for all of the above, including a wide range of PXIe solutions for test and measurement applications.

Its main benefits are its PXIe Chassis and System Controller, which can be customized to suit specific requirements based on its standard product portfolio. The PXIe Chassis are designed with EMC shielding in accordance with EN 61326-1 class B, ensuring that they meet even the most stringent requirements.

The PXIe System Controller is the smallest controller on the market, with only 4 HP width. By using COM Express modules, Schroff offers many processor options to choose from, allowing quick adaptation to the newest and most powerful processors on the market.

DIN Rail Mount Enclosures

DIN rail mounted enclosures are protective housings designed to be mounted on DIN rails, which are standardized metal rails used for mounting industrial control equipment inside equipment racks.

Electrical engineers, control panel builders, and industrial automation professionals use them to provide a secure, organized, and accessible means of housing electrical and electronic components such as relays, circuit breakers, terminal blocks, and control devices. These enclosures help streamline the installation process, ensure components are securely held in place, and provide easy access for maintenance and troubleshooting.

When sourcing DIN rail mounted enclosures, don’t just assume that a well-known name brand is going to give you the best product. Look for competitors that have advantages that set them apart:

- High-Quality Materials and Design: Italtronic enclosures, for example, are made from durable materials like polycarbonate and ABS, providing excellent protection against mechanical impacts, chemical exposure, and environmental factors.

- Modular and Customizable: Determine whether you need your DIN enclosures to be highly modular and customizable. Italtronic offer a range of sizes, configurations, and accessories, allowing for tailored solutions that meet specific project requirements.

- Aesthetic and Functional Design: Italtronic combines functionality with aesthetic design, offering customized UV digital printing, serigraphy, laser, and painting. Enterprise-scale companies will want to ensure that enclosures not only protect components but also enhance the overall appearance and branding of control panels and installations.

- Ease of Installation and Maintenance: Make sure your supplier facilitates easy installation and maintenance, with features like snap-on mounting and removable covers for quick access to internal components.

- Compliance and Certification: Italtronic enclosures comply with international standards and certifications, ensuring they meet stringent safety and performance requirements.

These features make Italtronic’s DIN rail mounted enclosures an appealing choice for professionals seeking reliable, versatile, and high-quality alternatives for industrial and commercial applications.

Manufacturers and Products:

- Italtronic: DIN rail mounted enclosures

- Wall-mounting enclosures and home automation

- Modular enclosures for DIN rail mounting

- Front panel mounting enclosures

- Enclosures with 8- and 11-pin guide sockets

Connectors

Electrical and electronic connectors are critical components used to join electrical circuits, ensuring reliable transmission of power and data. They provide secure and stable connections between cables, devices, and systems, enabling complex operations to function seamlessly.

For the purposes of this article, we also include in this category various EMI seals, foams, and gaskets; cable management and cable sleeving products; and wireless connectivity products and sensors. As you can see, connectors is a broad category in the world of manufacturing!

Made from conductive materials like copper or aluminum and insulating plastics, these components are essential across various industries, including automotive, telecommunications, industrial equipment, test and measurement, medical devices, agriculture, RV/marine & recreation, IT & computing, military & aerospace, appliances, EV charging, power generation and solar energy, and much, much more.

Moreover, there’s a whole industry devoted to protective sleeving and interconnective devices for these very connectors.

Circular Connectors

Circular connectors are versatile and widely used in various applications for their robust design and ease of use.

Sealed Circular Connectors. These harsh environment connectors feature a circular interface, designed for rugged and reliable connections in outdoor applications or under extreme conditions. The interface typically houses multiple pins arranged in a circular pattern, facilitating easy and secure mating and de-mating.

They are commonly used in aerospace, defense, industrial automation, and transportation. Made from high-grade plastics and metals, they ensure durability and resistance to dust, moisture, and vibration.

Overmolded Cable Assemblies. Overmolded cable assemblies feature a molded plastic covering over the cable and connector junction, enhancing durability, strain relief, and protection against environmental factors like moisture, dust, and chemicals. The benefits include improved longevity, reduced risk of connector damage, and better overall performance.

Switchcraft Conxall offers custom molded cable assemblies designed to provide durable and reliable connections in demanding environments. Their cable assemblies stand out due to their high-quality materials, precision engineering, and customization options tailored to industry- and customer- specific needs.

These assemblies are ideal for industrial, medical, military, and outdoor applications, ensuring robust and secure connections that withstand harsh conditions, thereby offering a competitive edge in quality and reliability.

Coaxial/RF Connectors. RF/Coaxial circular connectors are designed to maintain the integrity of high-frequency signals, ensuring minimal signal loss and interference. They are widely used by industries such as telecommunications, broadcasting, and aerospace, where precise and reliable signal transmission is crucial.

Constructed with a central conductor, insulating layer, metallic shield, and outer insulating layer, these connectors are made from high-conductivity metals like gold-plated brass or aluminum, and durable insulating materials. Typical applications include connecting antennas, transmitters, and receivers in communication systems, as well as linking test and measurement equipment.

Switchcraft-Conxall offers a comprehensive range of RF/coaxial circular connectors known for their durability and high performance. Their product line includes UHD MicroBNC connectors, DIN 1.0/2.3 connectors, and BNC connectors. They also offer in their general catalog products such as AC Power connectors, modular panel connectors, and high-quality XLR connectors.

Military-grade Connectors. Military-grade connectors are designed to withstand harsh environments and rigorous use. They feature robust construction with materials such as high-grade aluminum and stainless steel, offering superior durability and resistance to extreme temperatures, moisture, and vibration. They are commonly used in defense, aerospace, and other demanding applications where reliability is critical.

Switchcraft-ConXall offers both an off-the-shelf Mil-C-5015 Equivalent and Mil-E-Qual Series.

Known for their secure locking mechanisms, high pin density, and compliance with military standards, these connectors ensure reliable performance in mission-critical operations.

Manufacturers and Products:

Switchcraft-ConXall: NEW Micro-Con-X Series

Switchcraft-ConXall: Custom Factory Molded Cables

Switchcraft-ConXall: Coaxial/RF Connectors

Board-level Connectors

Board-level connectors are used to connect printed circuit boards (PCBs) within electronic devices, ensuring reliable signal and power transmission. These connectors are essential for maintaining the integrity and functionality of complex electronic systems commonly found in consumer electronics, industrial equipment, and computing devices.

Switchcraft-ConXall offers various categories of board-level connectors.

- Their DIN Panel Mount Connectors are designed for secure mounting, providing robust connections for various electronic applications. These connectors offer reliable performance, durability, and easy installation, making them suitable for industrial and commercial use.

- The NH Series Narrow Panel Mount Connectors are ideal for applications with limited space, offering a narrow profile for tight installations. These connectors provide high-density connections, perfect for compact electronic devices and equipment.

- The EH Series includes audio, video, and cable connectors, ensuring high-quality signal integrity. These connectors are versatile, easy to install, and suitable for professional audio/video equipment and data communication systems.

- Finally, the BKZ Series of DC power jacks and plugs are designed for right-angle mounting on PCBs, providing secure DC power connections. They offer durability, reliable power transmission, and a space-saving design, making them ideal for consumer electronics and portable devices.

Laird Dupont offers are variety of board-level components that we group under our Connectors pillar:

- Metal SMD contacts and soft SMD contacts for grounding and EMI

- Molded surface-mount inductors, wire-wound surface mount inductors, and wire-wound surface mount ceramic chip inductors for power and signal lines

- More than 500 standard fingerstock gaskets, as well as quick turnaround on custom precision parts

Manufacturers and Products

SwitchCraft-ConxAll: BKZ Series

Laird Dupont: Fingerstock metal gaskets

Electrical Connectors: Busbars and Fuse Blocks

Busbars

Used for distributing power in high-current applications, busbars offer a compact and efficient alternative to traditional cabling. Key considerations include the current-carrying capacity, voltage rating, and the thermal performance of the material. Copper and aluminum are common choices for busbars due to their excellent electrical conductivity and mechanical strength. Engineers should also consider surface treatments, such as tin or silver plating, to enhance corrosion resistance and ensure long-term conductivity.

Multilayer laminated busbars such as those made by the globally distributed manufacturer Mersen are ideal for applications requiring minimal inductance, such as in power electronics and renewable energy systems. These busbars reduce parasitic inductance and improve system efficiency by integrating multiple conductors with dielectric layers. Engineers must assess factors like dielectric strength, thermal conductivity, and the physical layout to match their system's requirements.

Terminal blocks, power distribution blocks, and fuse blocks

Terminal blocks are primarily used to securely connect and organize wires, ensuring reliable electrical paths while simplifying wiring and maintenance. Available in configurations like screw-in, spring-loaded, or push-in designs, terminal blocks cater to various installation needs and provide modularity for easy expansion. They are commonly found in control panels, distribution boxes, and industrial machinery.

Power distribution blocks, on the other hand, are designed to distribute electrical power from a single input source to multiple output circuits. They handle higher current loads and efficiently divide power among subsystems. These blocks are ideal for applications requiring primary power to be split into secondary circuits, offering fixed junction points. Mersen specializes in power distribution blocks, providing UL- and CSA-approved solutions that meet strict standards for feeder and branch circuits, with flexible configurations for different input and output needs.

Fuse blocks combine wire termination with overcurrent protection. They secure fuses and provide connection points for incoming and outgoing wires, protecting circuits by interrupting current flow when it exceeds safe levels. Commonly found in automotive, industrial, and consumer electronics applications, fuse blocks accommodate specific fuse types, such as blade or cartridge fuses, and are designed for straightforward maintenance and replacement.

The key differences lie in functionality: terminal blocks manage connections, power distribution blocks split and distribute power, and fuse blocks integrate circuit protection.

Manufacturers and Products:

Mersen: InfiniCell Monitoring Busbar

Mersen: Laminated Busbars

EMI Seals and Gaskets

EMI seals and gaskets are critical for mitigating electromagnetic interference while maintaining the integrity of electronic systems. When sourcing EMI seals and gaskets for PCBs, connectors, and electronic enclosures, engineers must prioritize performance, compatibility, and environmental considerations. Key factors include the material's shielding effectiveness, compressibility, and durability under operational stresses.

Conductive elastomers, often made with silicone or fluorosilicone bases infused with metal particles, provide excellent shielding performance and environmental sealing. These are ideal for applications requiring a balance of mechanical resilience and EMI suppression, such as in aerospace and telecommunications. Engineers should evaluate material compatibility with the enclosure's finish and consider resistance to temperature extremes, oxidation, and other environmental factors.

The EESeal from Quell Corporation is a unique product that turns any connector into a filtered connector in seconds. It is a custom-designed seal made of highly conductive silicone with embedded capacitors and multiple peripheral shell contacts.

The EESeal is meant for applications that have either failed EMC testing or anticipate failure, and for which redesigns are time- or cost-prohibitive. Long-lasting and effective, custom samples can be shipped in as little as 24-48 hours.

Fabric-over-foam gaskets are versatile and cost-effective solutions for applications like consumer electronics and IT equipment. They feature a foam core for compressibility, encased in conductive fabric for EMI shielding. These gaskets are suitable for low-pressure environments and can be shaped to fit complex geometries.

Ferrite-based solutions offer another approach to EMI mitigation. These are typically applied to cable interfaces and high-frequency environments. Engineers should consider their suitability for specific frequency ranges and their potential impact on signal integrity.

Customizable gasketing solutions, such as molded or die-cut gaskets, allow for precise fit and integration into unique enclosure designs. Selection often depends on design constraints, such as available space, required compressive force, and mounting conditions.

Manufacturers and Products:

Quell: EESeal

Laird Dupont: Fabric-over-Foam (FoF) gaskets

Cable Connectors and Sleeving

Cable Sleeving and Wrapping

Techflex engineers and manufactures a wide range of braided sleeving products for a variety of industries, from biomedical and aerospace to wire, hose, and cable bundling protection for automotive and transportation.

The Techflex catalog includes, but is not limited to, cable sleeving products for applications with the following requirements:

- Heavy duty, harsh-environment

- Electrical shielding and grounding (metal)

- Flame retardant and advanced materials

- High temperature

- Heatshrink tubing

- Lacing tape, cable ties, and other tools & accessories

Cable Management

The cable fastener by Encablist is engineered to enhance cable organization and management for professionals in engineering, data center design, and industrial design.

This system features robust interlocking plastic fasteners that snap together securely, facilitating efficient bundling and routing of cables without requiring additional tools or adhesives. Constructed from high-grade materials, these fasteners offer exceptional durability and reliability in demanding environments.

Engineered for versatility and simplicity, the Easy-Snap system allows for rapid installation and adjustment, making it ideal for dynamic cable setups often found in data centers and industrial applications. The reusable nature of these fasteners provides an eco-friendly and cost-effective solution, reducing the need for single-use cable ties and minimizing waste.

The system is adept at managing various types of cables, including power cords, network cables, and control wiring, thereby reducing clutter and enhancing operational safety by preventing cable entanglement and wear.

Encablist’s Easy-Snap system replaces zip-ties as a streamlined and organized approach to cable management.

Manufacturers and Products

Encablist: Easy-Snap system

Techflex: Dura Wrap

Wireless Connectors and Sensors

Winegard is one of the world's premier manufacturer of antennas and wireless connectivity products. While many of their offerings are directed at the RV/recreation market, the Iowa-based company is known for quickly producing high quality custom products for its OEM customers.

Cellular Range Extenders

Designing or sourcing cellular range extenders requires a deep understanding of RF (radio frequency) propagation and the specific frequency bands supported by the target networks (e.g., LTE, 5G). Engineers must evaluate whether the extender supports carrier aggregation and MIMO (multiple-input, multiple-output) for enhanced throughput.

Key considerations include the gain of the extender’s amplifier, measured in dB, and its compliance with FCC regulations to avoid interference with nearby cell towers. Antenna design is critical, with engineers weighing directional antennas for long-range applications against omnidirectional designs for coverage flexibility. Placement also matters; signal degradation due to obstructions like buildings or foliage must be mitigated. Thermal management is another challenge, as amplifiers in high-power devices generate significant heat that can affect performance.

WiFi Range Extenders

WiFi range extenders pose a different set of challenges, particularly in multi-user environments where interference and congestion are common. Engineers must determine whether dual-band (2.4 GHz and 5 GHz) or tri-band extenders are required, taking into account backward compatibility with older devices and forward compatibility with WiFi 6 or WiFi 6E standards. Placement optimization is critical to minimize dead zones while avoiding co-channel and adjacent-channel interference. Beamforming capabilities and MU-MIMO support can improve performance by directing signals toward connected devices, but these features increase complexity and cost. Engineers should also consider the extender's signal latency, which can degrade real-time applications like video streaming or online gaming. Hardware integration for PoE (Power over Ethernet) can simplify installation in commercial environments.

Satellite TV and Internet Solutions

For satellite TV and Internet systems, engineers must prioritize factors such as satellite alignment, signal attenuation, and environmental durability. Dish and antenna design is paramount, as small misalignments can lead to significant signal degradation. Engineers must account for the carrier frequency (typically Ku- or Ka-band) and potential rain fade, which disproportionately affects higher frequencies. Automatic or manual pointing mechanisms should be evaluated for their accuracy and ease of use. For Internet solutions, compatibility with standards like VSAT (Very Small Aperture Terminal) and support for protocols such as TCP acceleration are important for maintaining acceptable latency and throughput over satellite links. Hardware robustness against UV radiation, wind, and temperature extremes must also be considered, especially for outdoor installations.

Sensors for Indoor or Outdoor Use

Sensors for wireless connectivity applications, whether for environmental monitoring, motion detection, or other purposes, require careful consideration of their power source, connectivity protocol, and environmental durability. Engineers must decide between battery-powered sensors, which require low-power wireless protocols like Zigbee or LoRa, and wired options that may leverage WiFi or cellular networks. For outdoor sensors, IP ratings must be scrutinized to ensure resistance to water and particulate ingress, while UV-resistant materials are essential for long-term durability. Connectivity considerations also include range, latency, and interference susceptibility, particularly if the sensors operate in crowded ISM bands. Calibration and data integrity are critical for sensors in applications requiring high precision, such as industrial monitoring or weather stations.

Integration Considerations

Across all these product lines, integration with existing systems is a significant concern. Engineers must evaluate compatibility with protocols like TCP/IP, MQTT, or proprietary wireless protocols, depending on the application. Device firmware security is increasingly critical, with considerations for OTA (over-the-air) updates and encryption standards to prevent unauthorized access or data interception. Additionally, engineers must assess power requirements, considering whether the devices will operate from AC mains, DC power, or batteries, and how these choices impact energy efficiency and reliability.

Manufacturers and Products:

Winegard: RangePro cellular extender

Winegard: Starlink satellite internet

Winegard: Sensors (water leakage; temperature/humidity; door/window closures; motion)

Please note that products listed on Winegard's website are presented for retail/consumer market. Identical products and custom products are available for OEM customers.

---

Industry-Specific Applications and Products

Agriculture/Livestock

Commonly Used Products: Waterproof circular connectors, plastic electrical enclosures, DIN rail mount enclosures, braided cable sleeving [see also: HMI; Thermal Management]

Applications: Automated feeding systems, environmental monitoring & control, irrigation control, cable and electrical protection.

Example: Switchcraft-ConXall sealed circular connectors are used in automated irrigation systems to ensure reliable performance in wet conditions.

Appliances

Commonly Used Products: Standard circular connectors, rugged harsh environment sealed connectors, audio/video connectors, metal electrical enclosures (wall mount or 19” cabinet, braided cable sleeving, cable management systems (Encablist), DIN rail mounted enclosures, and busbars.

Applications: In HVAC systems, they protect and connect sensors, controllers, and actuators, ensuring efficient operation. In commercial kitchens, they manage power distribution and control signals in equipment like ovens, dishwashers, and refrigerators, enhancing safety and performance.

In industrial automation, these products are vital for controlling and connecting machinery. Additionally, in renewable energy installations and data centers, they help maintain power quality and reliability.

Example: Switchcraft-ConXall’s multi-pin sealed circular connectors Multi Con-X, Mini Con-X, and new Micro Con-X lines – are frequently used in outdoor and marine appliances to provide robust connections in high-vibration environments.

Electric Vehicle Industry

Commonly Used Products: High-current, harsh environment sealed circular connectors, metal instrument enclosures, DIN rail mount enclosures, automotive battery busbars, custom overmolded cable assemblies, harsh environment cable sleeving

Applications: Battery management systems, charging infrastructure, powertrain control.

Example: The Micro Con-X series of rugged, high-density connectors from Switchcraft-ConXall is known for its secure locking mechanisms and compact design, making it ideal for space-constrained environments in EVs.

HVACR and Mechanical Contractors

Commonly Used Products: Rugged pipe wrap and cable sleeving, waterproof circular connectors, plastic electrical enclosures

Applications: Climate control systems, refrigeration units, building automation

Example: Techflex's Dura HVAC Foam Protective Wrap is constructed of a tightly woven breathable polyester shell that offers protection from wind, rain, mildew, UV Rays and abrasion

Heavy Equipment/Machinery

Commonly Used Products: Standard circular connectors, metal electrical enclosures, PDUs with emergency stop, harsh environment braided cable sleeving

Applications: Construction equipment, agricultural machinery, mining equipment.

Example: Switchcraft-ConXall Micro Con-X connectors are used in mining equipment to ensure reliable connections in harsh, high-vibration environments.

IT and Data Center

Commonly Used Products: 19” cabinets, rack-mount instrument enclosures, PDUs with emergency stop, RF coaxial connectors

Applications: Server racks, networking equipment, data storage solutions.

Example: nVent Schroff's Varistar CP line of 19” cabinet systems are widely used in data centers for their modular design and advanced cooling options.

Industrial Equipment / Test & Measurement

Commonly Used Products: Standard circular connectors, metal electrical enclosures

Applications: Factory automation, control panels, robotic systems.

Example: nVent Schroff’s Rack Safety Plus is a fully configurable 19-inch PDU with built-in emergency shut-off, designed to save time, increase production speed, and drastically improve workplace safety.

Marine/RV and Recreational Equipment

Commonly Used Products: Waterproof sealed circular connectors, harsh environment braided cable sleeving

Applications: Navigation systems, onboard electronics, communication devices, docking equipment

Example: Switchcraft-ConXall’s Multi-Con-X Series connectors provide robust waterproof connections for marine navigation systems.

Medical Device

Commonly Used Products: Miniature sealed connectors, EMI/ESD filter seals

Applications: Diagnostic equipment, patient monitoring, surgical instruments.

Example: In MRI machinery, Quell’s EESeal turns connectors into a filtered connectors, eliminating EMI/RF interference

Military and Aerospace

Commonly Used Products: Mil-C-5015 equivalent & Mil-E-Qual connectors, ruggedized instrument enclosures, EMI filter seals, high-speed rugged backplanes, shock-mounted MIL901D/901E cabinets, high-thermal Card-Loks, rugged systems & VPX

Applications: Avionics, communication systems, radar equipment.

Example: nVent Schroff’s Varistar CP MIL901E cabinet, Military certified for shock, vibration, EMC, and corrosion, is used by major military contractors and government agencies for unique and sensitive applications that demand flexible design accommodation, superior lead time and competitive cost.

Power Generation

Commonly Used Products: Rugged sealed circular connectors, DIN rail mount electrical enclosures, customizable plastic enclosures, metallic and non-metallic EMI shielding, harsh environment braided cable sleeving, heat shrink tubing

Applications: Power distribution, control systems, renewable energy converters.

Example: Italtronic makes the number one selling modular plastic enclosures in Europe, and is quickly catching up in the United States for use in housing control systems, due to their customization, durability, competitive cost, and short lead times.

Solar Energy & Renewables

Commonly Used Products: Ruggedized, waterproof sealed circular connectors, plastic electrical enclosures, DIN rail mount enclosures, harsh environment braided cable sleeving, 19” inch cabinets

Applications: Photovoltaic systems, inverters, battery energy storage.

Example: Techflex’s Flexo® PET and Flexo F6® braided cable sleeving products are useful in covering and protecting wires and cables that connect solar panels to the inverter or charge controller. Their lightweight and flexible construction is helpful in tight spaces, guarding against UV, heat, abrasion, chemicals, and more.

Transportation and Rail

Commonly Used Products: Standard Circular Connectors, Metal Instrument Enclosures

Applications: Signaling systems, onboard communication, control systems.

Example: nVent Schroff's Small Form Factor Rugged Cases are flexible and proven rugged aluminum die-cast cases for harsh environment up to IP67. They offer a wide variety of footprints, with fan or conduction cooling solutions, mounting brackets, stabilizing feet, and much more.

---

Enclosures and Connectors by Product Category

Enclosures

19” Chassis, Desktop cases, cabinets, Rack mount cases, Subracks

AdvancedTCA

Backplanes

Board Retainers and Extractors (Calmark & Birtcher)

Board-level shielding

Cabinet doors, frames, and base plates

Door contacts

EMI/RF Enclosures

Enclosure Monitoring and Management

Enclosed breakers

Front Panels and Plug-in Units

Industrial controls

Inserters, extractors, levers, and ejectors

Management gateways

MicroTCA

Monitor and keyboard drawers

Open frame racks & ruggedized electronics cabinets

Panels for racks

PCB tainers, retainers, and card guides

PXI and PXI Express (PXIe)

Radome enclosures

Rugged/harsh environment electronics cases

Server and Networking Racks

Small form factor cases

Wall mount cabinets

Connectors

Antennas

Cellular signal boosters

Circular connectors & sealed circular connectors

Fabric-over-foam (FOF) gaskets

Fingerstock gaskets

Harsh environment connectors

Router signal extenders

Satellite internet dishes and receivers

Sensors

Waterproof connectors

Where to Go Next… (Hint: Contact Us)

For more information on products, applications, or to request samples, please contact ArKco Sales at (651) 777-7454, or arkco@arkco-sales.com.

To stay in the loop about the latest on products, news, and articles like this, sign up for a newsletter!

To follow our shenanigans in the world of electromechanical manufacturing—including trade shows, lunch-and-learns, webinars, white papers, and other product news and industry trends—check out our LinkedIn page!

Unlike most newsletters that clog your inbox and are driven by a sales-first focus, these are written for engineers by real humans. Your information is always safe with us, and you can unsubscribe (easily!) at any time.

Sign up for exclusive content by visiting our newsletter signup page.

Beyond Enclosures & Connectors

ArKco Sales is your guide and source for electromechanical systems and components across a broad range of industries and applications. In addition to Enclosures & Connectors, we provide expertise and connect you with manufacturers in the following categories:

• Power

• Thermal

• HMI

• Electrification