CLEVELAND, Ohio – Laird Performance Materials continues to focus on innovation with its release of its Tflex™ SF10 Series, a silicone-free gap filler combining 10 W/mk thermal conductivity with superior pressure versus deflection characteristics, enabling it to exert minimal pressure on delicate components.

Along with no silicone and its high thermal conductivity, a key differentiator of Laird’s Tflex SF10 is that very little pressure is required on fragile integrated circuits and other components. This gives design engineers a new means to attain the lowest possible thermal resistance.

“We anticipate seeing strong market interest in this breakthrough gap filler,” says Mark Wisniewski, Laird product line director.

“Automotive sector component suppliers as well as makers of routers, hard disk and solid-state drives, wireless products, drones, satellites, gaming systems, and smart home and portable computing devices all need high conductivity and component-protecting solutions.’

Test results available from Laird show Tflex SF10 exhibits no oil bleed or leakage after an extended period. No or minimal oil bleed is an important factor evaluated by device manufacturers.

Tflex SF10 has no fiberglass reinforcement, provides excellent surface wetting for low contact resistance, and exceptionally low thermal resistance. It is suitable for applications in operating temperatures ranging from -40C to 125C. Tflex SF10 meets regulatory requirements including RoHS and REACH.

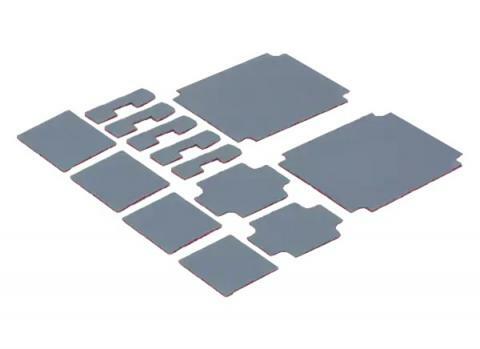

Laird’s newest gap filler is available in thicknesses ranging from 0.50mm (0.020”) to 4.0mm (0.160”), in standard sheet sizes of 18” x 18”, 9” x 9” or custom converted die cut parts, as shown in the photograph.

About Laird Performance Materials

Laird Performance Materials, a portfolio company of Advent International, enables high-performance electronics. We create advanced protection solutions for electronic components and systems. World-leading technology brands rely on us for improved protection, higher performance and reliability, custom structural designs, and faster time-to-market. We solve design issues through innovative products such as EMI suppression or absorption materials, thermal interface materials, structural and precision metals, magnetic ceramic products, and multi-functional solutions. This latter product family solves multiple EMI, thermal and structural design issues simultaneously using a single process design. Visit Laird at https://www.laird.com